Stamp Out Downtime with a Dynamatic CES Press Drive Unit

Mechanical CES Press Drives from Dynamatic

Mechanical CES Press Drives from Dynamatic

The CES (Constant Energy System) controller and eddy current mechanical drive unit are applied in stamping press applications. The name, Constant Energy System, is derived from the physical arrangement of the components of the system, the flywheel of the eddy-current drive, coupled to a constant speed motor. Therefore, constant kinetic energy is maintained in the flywheel. After the slide velocity is almost completely at rest, they provide the starting torque and braking action that are required without the need for physical contact between the drive shaft and the crankshaft, or the crankshaft and the holding brake unit. This eliminates the periodic replacement of clutch pads by removing the air actuated clutch and only utilizing the folding brake to stop movement at low slide velocity and to hold slide position. The largest advantage is the ability to slow the slide velocity during the cycle by reducing the clutch action and using the eddy current brake portion of the mechanical unit, to slow the slide to the desired working speed. At this point the braking action stops and the clutch portion provides the necessary driving torque through the material.

If required, upon exiting or passing the bottom of the stroke, the clutch portion could accelerate the slide to a higher rate of speed or the same rate as during the initial start of the cycle. Because of the flexibility within the system this allows for an overall greater number of parts per hour by means of a higher average rate of strokes per minute.

The unique advantages of the eddy current CES press drive are:

- CES Press Drives can function within a wide stroking range while exercising full control of the slide within individual strokes. These press drives can produce sufficient inertia for normal, double and triple action press applications

- Blanking, deep draw transfer, progressive die, follower, synchronized and multiple action presses can fully utilize all of the CES Press Drive features

- Clutch/brake design of the CES Press Drive help avoid “tearing” of pressed metal parts, optimizes parts per minute production

- Single CES system saves capital and maintenance costs compared to multiple servomotor design

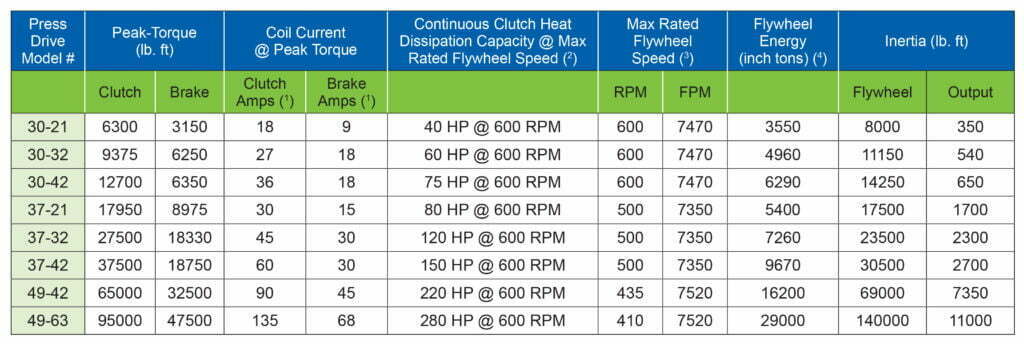

Specifications and Engineering Data

Dynamatic Digital CES Press Drive Controllers

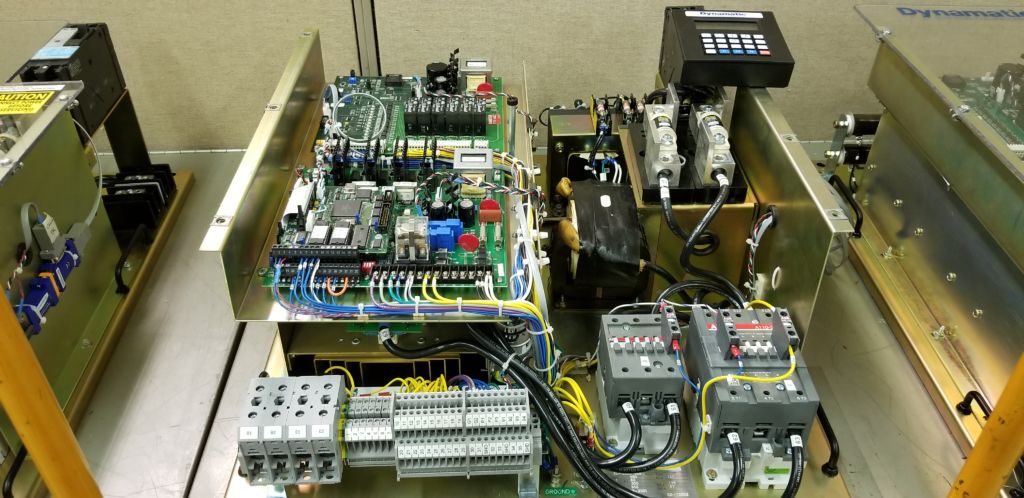

Our CES Press Drive Controllers are solid state closed loop velocity controllers specifically designed for Eddy Current CES mechanical press drives, creating a simple, safe, and reliable drive system.

Our CES Press Drive Controllers are solid state closed loop velocity controllers specifically designed for Eddy Current CES mechanical press drives, creating a simple, safe, and reliable drive system.

CES controllers are readily adaptable to position control in large production presses. These systems utilize a position transducer (digital shaft encoder) to measure press position (crank angle) and compares this feedback information with a digital position reference.

Easily applied to single or multiple action presses where speed control is desired. The system offers many unique features not available with other press drive designs for use on draw presses, blanking presses, transfer presses and on synchronized presses with automated handling equipment

100% Factory Tested

Digital CES press drive controls and all individual components are 100% factory tested under simulated load-operating press control conditions. Testing is done by using a custom-built burn in test chamber designed to operate at all voltages, under full load, and using actual coils from a working CES mechanical drive. This test chamber also exposes the controller to rigorous vibration and extreme heat similar to working press environments. These test will meet or exceeds the highest industry standards on any press drive controllers available today.

- Servo control in one (1) simple package

- Microprocessor based control ensures maximum operation flexibility and reliability

- Maximum production with minimum scrap… precision speed control maintains fixed flywheel up to a 5:1 speed range

- Press logic safety circuits protect both operator and machinery

- Low speed controls with no additional cooling, eliminates the need for die setup motor

- Intra stroke speed changing permits deep drawing without waste or excessive lubricant

Certified Factory Re-manufacturing

Don’t trust the heart of your press to just anyone… Insist on Dynamatic quality.

Drive Source International offers quality re-manufacture CES press drives and repair for all Eddy Current drives and controllers. We have been designing, building and refurbishing systems for over 65 years and know more about our equipment than anyone else. We have original specifications, drawings, documentation, test requirements and update information. To keep your business running strong, you need the kind or re-manufacture/repair that only the original manufacture can offer.

- All eddy current drives and controllers

- Our experienced drive technicians dismantle and assess your drive and all individual components

- Replace all damaged and worn components with new factory warranted parts

- All re-manufactured drives are 100% tested to original Dynamatic specifications certifying quality and performance

- Circuit board analysis, repair and testing per Dynamatic standards