What Does a Variable Speed Drive Do?

A variable speed drive, or VSD, can vary the speed of an otherwise fixed speed motor by controlling the speed and torque. In our case, a clutch is attached to an AC induction motor and affixed to other equipment to ensure the speed of the equipment is controlled on demand and with precision. VSDs provide more precise control of the machine output and have soft starting capabilities, which prolong the life of the equipment. In eddy current VSDs, there is no physical contact between the input and output members of the drive, which ensures little maintenance and long equipment life.

How Do Variable Speed Drives Work?

VFDs convert the fixed frequency and voltage input into a variable frequency and voltage output. VSDs work in a different fashion, learn how eddy current variable speed drives work in this video: https://youtu.be/io9xPmOqCOU

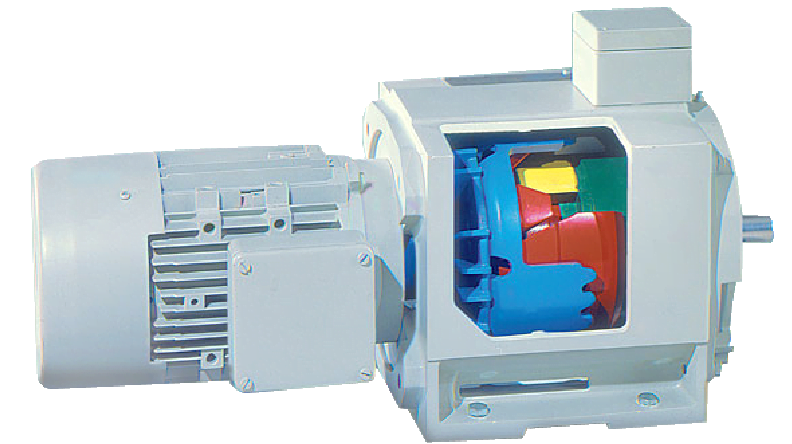

In our case, a fixed speed AC induction motor is fitted with a rotating drum on the motor shaft. An electromagnetic coupling is used to vary the speed of the output. The only contact points between the drum and output coupling are bearings. The motor and coupling are separated by an air gap. By regulating the voltage to the clutch coil inside the coupling, a magnetic flux field is created within the air gap between the clutch drum and clutch coupling. The distortion of this flux field creates torque. The greater the power sent to the coil, the greater the torque.

What Uses Variable Speed, or Adjustable Speed?

Equipment such as conveyors, feeders, winders, stamping presses, pumps and fans can benefit from varied speed. Eddy Current Variable Speed Drives are not limited to these applications, however. Find out if your equipment could benefit by sending an email to sales@dynamatic.com.

Why Use Eddy Current Variable Speed Drives?

- Decreases energy consumption

- Longer lifespan of your equipment

- Reduces heat and noise in your facility

- Lower installation costs

- Lower operating costs

- Less maintenance, repair and downtime