There’s no doubt that downtime causes costly headaches and needs to be minimized. Not only do you have to count the operator wages, but overtime hours should also be considered, as well as any expedited shipping fees to ensure your orders arrive as quickly as possible. In many industries that could cost as much as $25,000 an hour, or even more!

Identify Critical Equipment

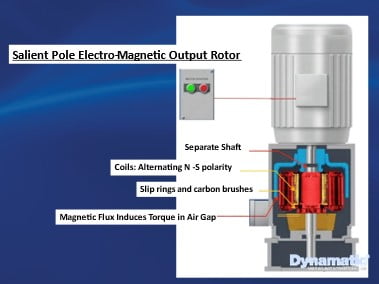

It’s not difficult to minimize downtime in your facility if you identify key process components like your variable speed drives. You should note the age of your variable speed drives and update them as needed to avoid future headaches. If it is a Dynamatic device, it’s generally good for several decades, but our products are mechanical and can fail. The age of your Dynamatic unit may not be readily seen on a name plate, but you should be able to tell if it’s more seasoned. If you have a Dynamatic unit, email us at sales@dynamatic.com or call us at (262) 554-7977 with your model number and we can look up the age!

Basic Maintenance Is Key

If you haven’t kept up with regular, preventative maintenance on your eddy current product, failures are bound to happen sooner than later. Preventative maintenance is fairly simple on an eddy current drive. We recommend that you lubricate the bearings every six months or so, and regularly check for dirt and debris in and around your unit. No headaches here!

Do You Have a Spare?

Chances are, once you’ve calculated downtime costs, you’d realize it is far more expensive than keeping a spare eddy current product on your warehouse shelf.

Imagine you’re a manufacturing company and your variable speed drive went down due to a mechanical failure. Turnaround time, including shipping, could be two weeks. As an example, two weeks at $25,000 an hour is a whopping $8.4 million!! That’s a bit of an exaggerated example, but with all costs calculated, it wouldn’t be that far-fetched.

A typical eddy current drive could cost thousands of dollars, depending on the required application. That’s a drop in the bucket compared the potential millions if your production had to be down for several weeks.

Due to the expansive variations of our customer’s requirements, we cannot guarantee to have your specific product available at the exact time of need. That’s why we feel it’s critical that you consider putting identical equipment on your shelf as a spare.

We’re making sure our customers are aware of the opportunity to save future headaches. We want to eliminate problematic down time, so when mechanical failures or accidents happen, you won’t be caught with a large expense.

Contact us for The Cure!