People most often talk about efficiency and harmonics when discussing variable speed, but there is a mechanical side to variable speed drives and the benefits are significant with an eddy current drive. Let’s take a look.

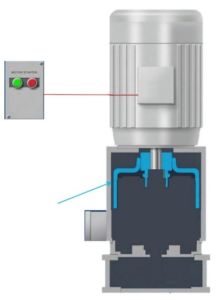

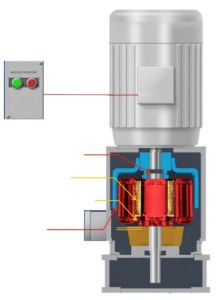

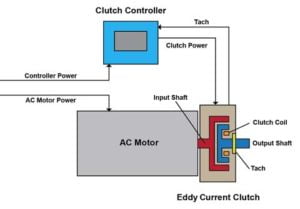

In an eddy current drive, the motor and driven equipment are not physically connected. The input and output shafts turn independently. The motor end is within the frame of the drive unit, and an open-ended cylinder is coupled to the motor shaft. (Figure 1) Attached to the driven equipment is the output rotor (Figure 2). This rotor has the coil which receives excitation from a small DC current to form a magnetic field. This field then transmits the torque from the motor to the driven load. (Figure 3).

Figure 1 Figure 2 Figure 3

The mechanical advantages of an ECD allow:

- Start and stop equipment without regard to the motors starting and stopping limitations. The motor will run continuously at design speed but unloaded.

- Start the motor unloaded.

- The design promotes starting the motor under no-load condition, extending motor life

- This results in cushioning between the drive system and load, permitting longer life for the machinery involved

- One way this is beneficial is if you are running equipment that is subject to blockages – it avoids tripping circuits

- If the driven equipment gets jammed/overloaded the motor shaft is unaffected.

- Motor is always running at design speed. This provides maximum cooling to the motor helping extend the motor life.

- Ramp-up load – Increase the load speed as slowly or quickly as needed for the process.

- No harsh service or temperature – neither the eddy current coupling nor the controls need air conditioning. Like the motors that drive them, the variable speed electro-magnetic drive unit is easily cooled with ambient air.

- Ability for multiple starts and stops eliminates Peak Demand charges.

Other mechanical advantages:

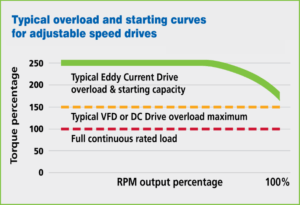

- High starting torque – intermittent availability of up to 250% of the rated motor torque. (See overload curve below)

- Dynamatic drives deliver full torque throughout the speed range (0-100%).

- A constant torque load is characterized as one in which the torque is constant regardless of speed.

- The horsepower requirement is directly proportional to the operating speed of the application and varies directly with speed.

- Since torque is not a function of speed, it remains constant while the horsepower and speed vary proportionally.

With a typical life cycle of 40-60 years, Dynamatic drives are the longest lasting variable speed drive system if they are maintained properly.

SIMPLE MAINTENANCE

Eddy current drives are maintained much like a motor. Every 6-12 months:

- Grease bearings

- Replace brushes, if applicable

- Clean dust/ debris out of enclosure